Technical Specification

- POWER- 30 -355 HP /22 -250 KW

- PRESSURE-6 - 10 BAR

- FLOW-155-2120 CFM /4.4-600 M3/MIN

- APPLICATION-TEXTILE,CEMENT,SUGAR,PLASTIC,PACKAGING

Some of the advantages of single stage screw compressor are as follows:

- High efficiency

- Low maintenance

- Quiet operation

- Compact design

- Suitable for various industries

Product Details:

| Unit of Price | Piece/Pieces |

| Price | 5000 INR |

| Unit of Measure | Piece/Pieces |

| Material | iron |

| Air Flow Capacity | 28-134 Cubic Feet Per Minute (ft3/min) |

| Warranty | 1 year |

| Working Presssure | 7-12.5 bar |

| Condition | New |

| Motor | 10-30 HP |

| Color | Blue |

| Dimensions | 950*870*1230 Millimeter (mm) |

| Driven Method | Belt driven |

| Width | 600-870 Millimeter (mm) |

| Usage | Industrial |

| Height | 850-1230 Millimeter (mm) |

| Weight | 220-540 Kilograms (kg) |

| Product Type | Belt driven screw compressor |

| Length | 850-950 Millimeter (mm) |

| Voltage | 440 Volt (v) |

| Lubrication Type | Lubricated |

| Delivery Time | 5 Days |

| Main Domestic Market | All India |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Central America Asia Australia North America South America Western Europe Middle East Eastern Europe Africa |

| Payment Terms | Cash Against Delivery (CAD) Letter of Credit (L/C) Cash Advance (CA) Cash in Advance (CID) Cheque |

| Supply Ability | 10 Per Week |

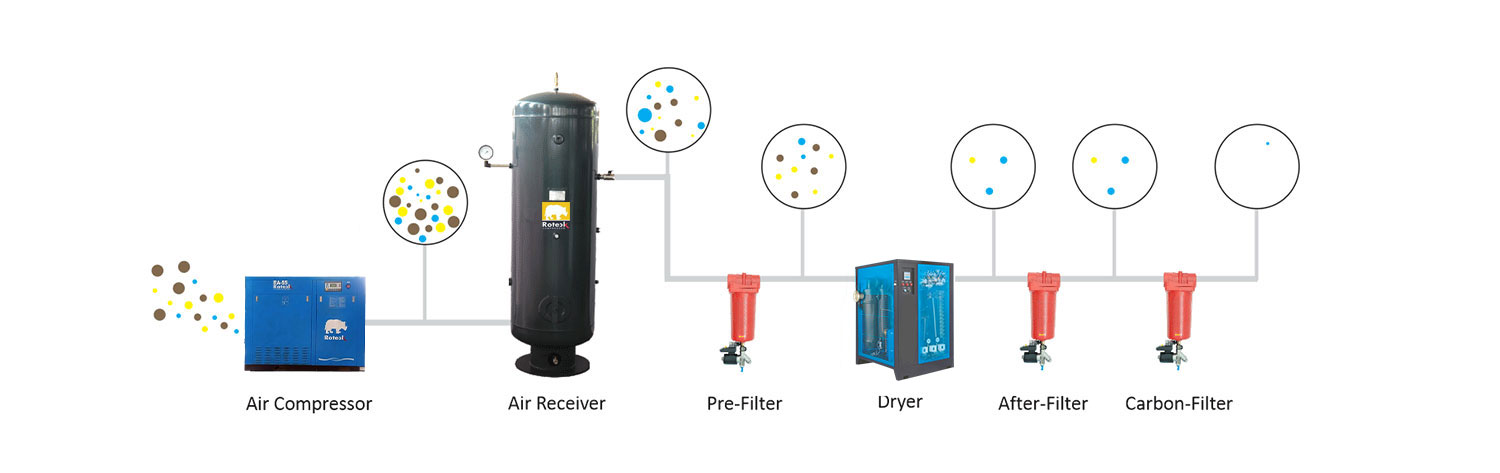

Typical Air Supply System

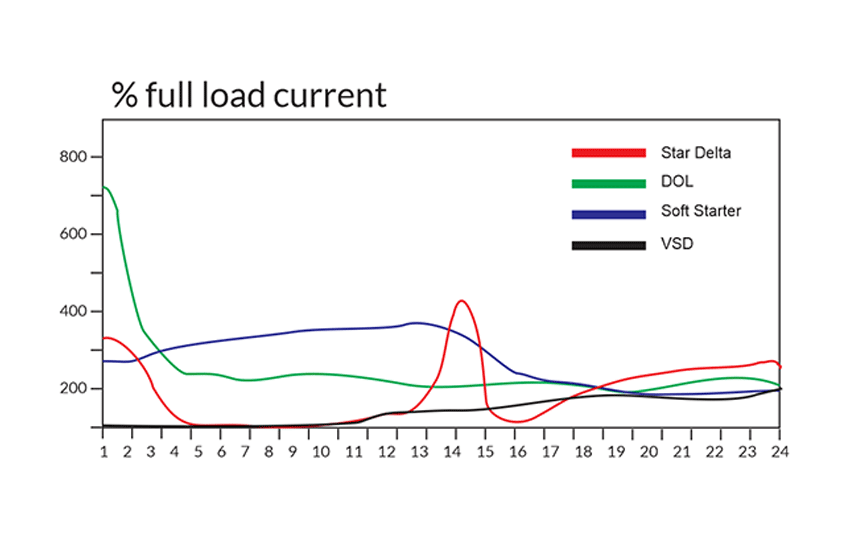

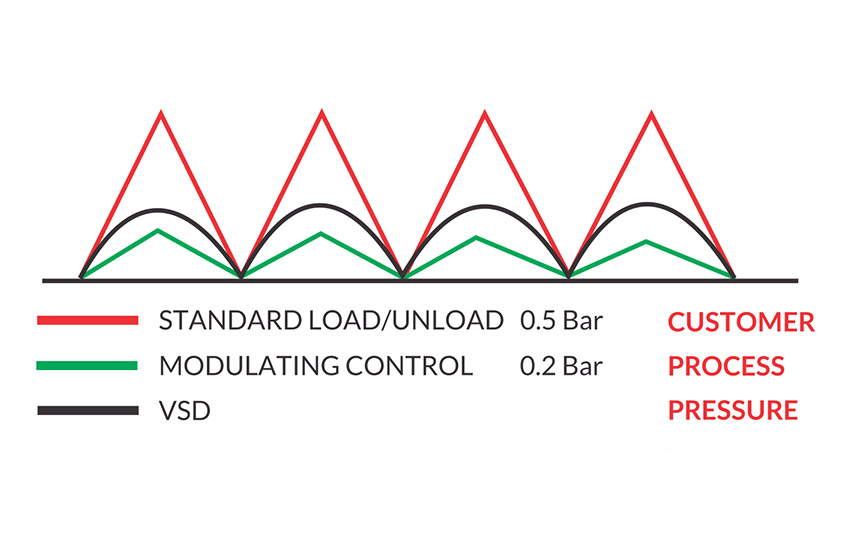

Power Saving with VSD